The UK produced less oil in the fourth quarter of 2012; the closure of Coryton in July 2012 was a key factor says a recently published report.

Last month the Department of Energy and Climate Change published its Energy Trends and Quarterly Energy Prices covering new data for Q4 2012 and provisional annual data for 2012.

Key findings

• The UK’s total energy production was 10½% lower than in 2011

• Imports in 2012 were at a record high, with exports at their lowest level since 1989

• Oil production was 14½% lower than in 2011 – the lowest annual production volume since the current reporting system began

• Production of petroleum products was down 8½%, with the closure of Coryton in July 2012 a key factor

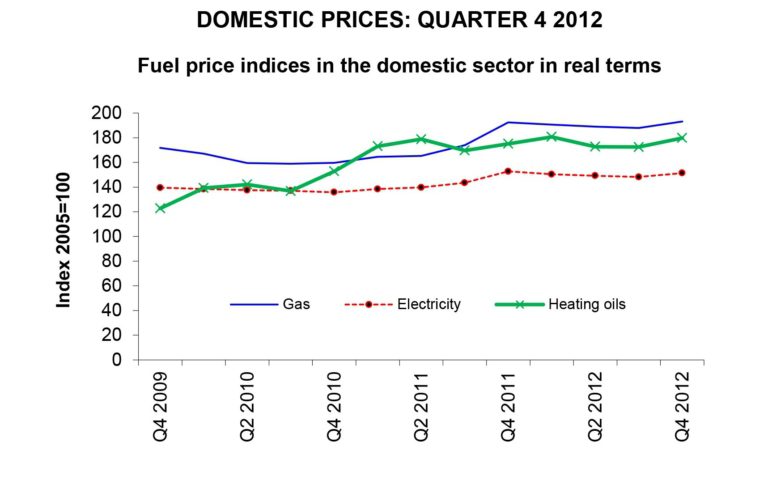

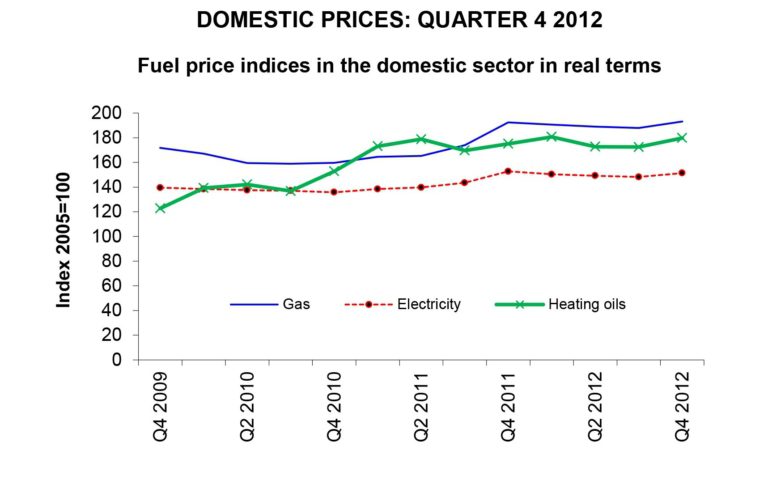

• Compare to Q4 2011, the cost of heating oil increased by 2.7%

• Based on a fixed consumption level of 3,300 kWh, the average electricity bill in 2012 increased by £26, compared to 2011

• Based on a fixed consumption level of 18,000 kWh, the average 2012 domestic gas bill rose by £81, compared to 2011

Oil quarterly tables ET 3.1 – 3.7 are available on the DECC section of the gov.uk website at:

www.gov.uk/government/organisations/department-of-energy-climate-change/series/oil-statistics

Energy Trends and the Quarterly Energy Prices bulletins, published quarterly, are available in hard copy from DECC on subscription, price £40 per annum and on the DECC section of the gov.uk website at

www.gov.uk/government/organisations/department-of-energy-climate-change/about/statistics

Moving the load was a complex technical operation – it took six hours to transport the head from Ellesmere Port docks to the refinery four miles away

Vital to Stanlow’s annual production of three billion litres of petrol, Essar Oil (UK) recently took delivery of a 450 tonne steel regenerator head for its residue catalytic cracking unit.

Its delivery is part of a planned £23million refurbishment project for the unit, which is the largest of its kind in Europe. The unit is being prepared for a major refurbishment later this year, of which the replacement of the giant head is a key element. It will give the refinery unit another 25 years of life.

Volker Schultz, chief executive officer, said: “The project represents a significant multi-million pound investment and is further proof of our determination to ensure Essar Oil UK is sustainably profitable and growing moving forward.

“The Stanlow refinery – the UK’s second largest refinery producing 15% of the UK’s transport fuels – is a major economic driver in the north west and this is a clear demonstration of our confidence in its future growth.”www.essar.com

Since the incident at Buncefield in December 2005 changes have been made in the regulatory approach to fire precautions at such installations. The EI Model Code of Safe Practice Part 19: Fire precautions at petroleum refineries and bulk storage installations provides updated guidance

The Energy Institute (EI) has updated its guidance on fire precautions measures to reduce the risk from fires at installations that process and store crude oil, petroleum, intermediates and refined products

The updated EI Model Code of Safe Practice Part 19: Fire precautions at petroleum refineries and bulk storage installations covers prevention through to detection, protection systems and mitigation measures and looks at selecting, implementing and monitoring the continuing performance of installation-specific justified risk reduction measures.

It supersedes the second edition which was being finalised at the time of the Buncefield bulk storage installation major accident in December 2005. Since then there have been changes in the regulatory approach to fire precautions at such installations, encompassing fire prevention measures, incident detection techniques, fire-fighting and response and emergency planning requirements. Among others, there have also been major changes in Part 19 to:Enhance guidance on consideration of environmental impacts of fire-fighting and the need for environmental risk assessment Provide guidance on fire response for ethanol and related polar substance handling/storage.Include guidance on potential scenarios, the role of congestion, incident consequences and examples of substances with a propensity to form large flammable vapour clouds.Clarify basis for determining whether scenarios are credible by referencing their likelihood to risk tolerability criteria.Provide guidance on passive fire protection (PFP) maintenance, fire water systems and detection systems.Provide guidance on vulnerability and siting of critical equipment and resources.

The guidance in this publication should assist process safety engineers/advisors, designers, emergency planners or others with responsibility for fire and explosion hazard management to meet the requirements of the European Seveso II Directive.The EI Model Code of Safe Practice Part 19: Fire precautions at petroleum refineries and bulk storage installations can be ordered at www.energypublishing.orgISBN: 978 0 85293 634 4Price: £165.00

“Failure to install a storage tank correctly can cause irreparable damage and significantly reduce operational life,” says Carbery’s John Switzer

An all Ireland oil tank survey has revealed that 78% of installations completed in the last 10 years were non-compliant with at least one OFTEC tank installation requirement.

The Carbery Plastics survey analysed compliance with OFTEC storage tank installation requirements at 150 domestic heating oil storage installations across Ireland.

In the Republic of Ireland, environmental protection was the biggest issue with 72% of surveyed tanks incorrectly specified as single skin tanks at installations where a bunded tank was required.

In Northern Ireland, fire protection was the biggest issue, with 60% of tanks non-compliant with fire safety requirements.

Carbery’s John Switzer said: “When installed in accordance with OFTEC requirements, modern plastic oil tanks can provide many years of reliable, dependable service. However failure to install a storage tank correctly can cause irreparable damage and significantly reduce operational life. Non-compliance with installation instructions and statutory requirements means that some technicians are exposing themselves and their customers to unwelcome and wholly unnecessary risk and liability.”www.carberyplastics.com

More

Is the present obligation on suppliers to hold stocks the most efficient model or would a centralised stocking agency be more appropriate? Your views are sought by 7th June.

“We are launching this consultation to ensure our oil stocking system continues to follow best practice, remains fit for purpose and provides the foundation to a vibrant UK oil industry,” said energy and climate change secretary, Edward Davey.

At UKPIA, director general Chris Hunt welcomed the government’s consultation: “We would support the establishment of an independent stockholding agency to manage the Compulsory Stock Obligation (CSO) going forward. We welcome DECC’s commitment to examine the case for this approach, and look forward to responding to this key consultation.”

The Downstream Fuel Association also supports the consultation and DECC’s consideration of a centralised stocking agency, in particular. Chief executive Teresa Sayers said: “This is a unique opportunity to ensure the UK finds the most cost effective way to comply with its international oil stocking obligations.”

Have your say in the consultation by clicking here.

Responses are requested no later than 7 June 2013 and should be emailed to deccdownstreamoilteam@decc.gsi.gov.uk or, if in hard copy, to David Rolfe Department for Energy and Climate Change (Area 3E), 3 Whitehall Place, London, SW1A 2AW.

Official published figures in Energy Trends March 2013 showed the UK had stocks equal to around 84 days of average consumption are available by clicking here.

The removal of proposals for a much reduced NOx emission level and a penalty on non-modulating domestic oil-fired boilers are ‘extremely positive for our industry’ says Jeremy Hawksley

When the European Commission published the draft Energy-related Products Directive six years ago, the future of the oil-fired heating sector looked bleak. Following a long campaign OFTEC has won a ‘significant victory’.

The proposed directive would have required NOx emissions levels from boilers of well below 100 milligrams per kilowatt hour. Had these limits been accepted it would have destroyed the UK and Irish oil heating industry overnight because it would have been impossible to reduce boiler emissions to the proposed levels.

However, after extensive lobbying by OFTEC and its European industry partner Eurofuel, the recently published directive has set the maximum NOx emission limit at 120 milligrams per kilowatt hours for oil boilers – a figure manufacturers believe is achievable, and are happy to work towards.

Commenting on the news, OFTEC director general Jeremy Hawksley said: “We’ve worked tirelessly with our industry partners in Europe to secure this realistic figure for NOx emissions, which is extremely positive for our industry. The new standard for oil boilers has been deferred until 2018 instead of 2016 as previously proposed, which will give manufacturers the necessary lead time to implement any product changes.

“The proposed penalty for non-modulating domestic oil-fired boilers has also been removed, which was also a significant threat to the oil industry. These positive outcomes are a direct result of the important work that OFTEC does in lobbying for the oil fired sector both at UK and European level. Without this action it probably would have been unfeasible to manufacture an oil fired boiler after 2015/16.” www.oftec.org

Although the government says it ‘remains committed to introducing a Renewable Heat Incentive (RHI) scheme for householders,’ the scheme’s introduction has been further postponed. It is now expected to be up and running in spring 2014.

Details about how the RHI scheme will work, together with tariff levels, will be published this summer with research into householder views on renewable heat helping to inform the scheme’s design.

In the meantime, the Renewable Heat Premium Payment (RHPP) scheme, which offers money off biomass boilers, solar thermal panels and heat pumps, has been extended until the end of March 2014. RHPP is targeted largely at those living off grid.

An RHI scheme for industrial and commercial customers was launched in November 2011. DECC plans to carry out a review of the tariffs under this scheme to drive forward further uptake.

Due to be launched on 1st January 2014, the scheme manager for the Petroleum Driver Passport (PDP) is the Scottish Qualifications Authority (SQA).

The scheme manager appointment follows a tendering exercise which saw SQA meet the quality and delivery requirements set by the UK Downstream Oil Distribution Forum (DODF).

Brian Worrall, DODF independent chair welcomed the appointment: “We continue to make rapid progress towards the launch of the PDP. SQA bring valuable experience and expertise which will ensure the quality and credibility of the PDP.

Detailed work is now underway to ensure that the PDP will be launched on schedule. The PDP will give assurance to fuel terminal operators, customers and the wider public that all tanker drivers have a common core of tested knowledge and competence in the loading, driving and off-loading of fuel tankers. It is supported by the PDP training standard which all tanker operators will be able to use as the basis of driver training and development.

The PDP builds on the knowledge already tested in the ADR certification process, incorporating additional knowledge and a practical assessment of skills. It includes content specific to five industry sub sectors; home heat, commercial, aviation, retail and marine.

Delivered through a combination of in-house or third party training and assessment providers accredited and audited by SQA, the passport will be valid for 5 years and will include an annual refresher day and both a written and practical assessment.

Email: john.bowman@skillsforlogistics.org

Officially launching the new filling station – CNG Services John Baldwin and Edward Timpson, MP for Crewe and Nantwich

The UK’s first compressed natural gas (CNG) filling station opened recently in Crewe. Local MP Edward Timpson officially opened the event, which attracted interest from companies across the UK.A range of cars, light commercial vehicles, buses and trucks which can run on CNG are already on the market but as yet there has been little interest from the fuel tanker market.The filling station is the largest such facility in the UK, offering a reliable fuel supply with capacity to fill 500 HGVs a day via three fast-fill hoses. The unmanned station will be used initially by commercial vehicles, providing transport and logistics operators in the area with a chance to incorporate CNG vehicles into their fleets.John Gavin, managing director of CNG Services, which will operate the station said: “The interest in CNG is being driven by the huge cost savings it offers – between 30 and 40% in comparison to diesel – and also because it is much cleaner. There are very significant savings of CO2, NOx and particulates from biomethane compared to diesel. It’s an excellent fuel as it performs well with low emissions and almost no carbon residuals.”

www.cngservices.co.uk

Most Read