In today’s world, it’s not just about managing fuel; it’s about mastering it, and the need for intelligent fuel management has never been more apparent. OTS Group designs and delivers practical answers to complex fuel storage, re-fuelling, distribution, service and maintenance issues read on for their top 5 ways to use technology for smarter fuel management.

1. Automatic Vehicle Identification (AVI)

This technology helps organisations “monitor fuel through the entire cycle,” says Shaun Ferrara, Sales Director at OTS Group. Automatic Vehicle Identification (AVI) is a specialised technology that uses radio-frequency identification (RFID) tags and sensors to precisely identify vehicles at the fuel pump. This technology empowers organisations to have full control over their fuel dispensing process, allowing for accurate and secure allocation of fuel to designated vehicles. By ensuring that fuel is only dispensed to authorised vehicles, AVI technology significantly enhances fuel management, reduces the risk of unauthorised refuelling, and prevents fuel theft from the nozzle.

2. Telematics integration

Telematics is a transformative technology that serves as a linchpin for cost reduction across multiple facets of fleet management. Beyond merely tracking fuel levels, telematics provides deep insights into real-time fuel consumption patterns, engine idling times, and even unauthorised refuelling activities. This granularity of data empowers companies to identify inefficiencies and enact prompt corrective measures. Moreover, the predictive maintenance capabilities of telematics monitor key engine metrics to pre-empt costly breakdowns, while driver behaviour analytics flag fuel-consuming behaviours like harsh braking or rapid acceleration.

In addition to telematics’ driver behaviour monitoring features, telematics systems incorporate GPS and real-time traffic data for route optimisation, leading to tangible fuel savings as well as helping organisations to comply with ever-tightening emissions and fuel consumption regulations by automating data collection, thus helping to avoid potential fines. The real-time tracking capabilities of telematics can also allow for immediate response to emergency situations such as vehicle theft, helping mitigate losses. In essence, telematics offers a multi-pronged approach to cost reduction, making it an indispensable tool in modern fuel management.

3. Predictive analysis and AI

Don’t just react to issues – predict them. Advanced AI algorithms analyse your data to identify trends and foresee issues before they happen. This is proactive fuel management at its finest. The advent of technology, particularly AI and machine learning, is ushering in a new era of predictive maintenance, allowing companies to identify and address mechanical issues before they escalate into costly breakdowns. These intelligent systems continuously analyse data points – from engine performance metrics to fluid levels and vibration patterns – to detect anomalies or trends that might signify a pending problem. By applying advanced algorithms to this data, AI can predict when a part is likely to fail or when maintenance is due, enabling timely interventions. This not only minimises downtime but also extends the lifespan of machinery, thereby maximising ROI. Preventative actions can be automated or triggered for manual review, turning maintenance from a reactive task into a proactive strategy. In this way, technology empowers companies to stay ahead of potential issues, reducing costs and enhancing operational efficiency.

4. Technology to improve safety and security

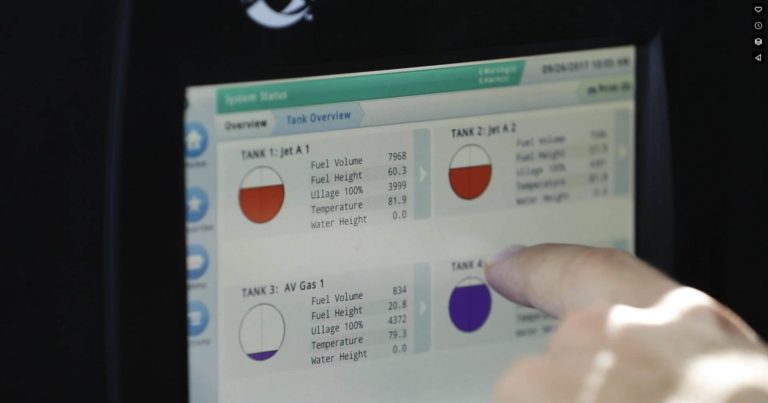

Companies can significantly enhance on-site safety and security by integrating a range of technology solutions. For instance, advanced surveillance systems with real-time customisable alerts allow for immediate responses to irregular activities, like unauthorised panel access for example. Speed sensors on forecourts can monitor vehicle movement to prevent accidents, while ambient light sensors ensure optimal lighting conditions for safe operation. Further, remote monitoring capabilities, using advanced PLC and HMI panels, offer seamless integration with existing security systems for round-the-clock vigilance. These technologies collectively provide a robust framework for a safer, more secure operational environment.

5. Improve lane utilisation

Companies can optimise lane use and ease the demand on a single, frequently used pump by employing intelligent technologies like sensor-driven signage and traffic management systems. By providing real-time indicators, such as lights or digital displays that guide drivers to available lanes, the technology helps distribute traffic more evenly across multiple pumps. This avoids long queues and waiting times at the most popular pump, usually pump number one, thus improving the overall efficiency and user experience at the fuelling site.

Distributing traffic more evenly across multiple pumps not only enhances efficiency and user experience, but it also extends the lifespan of the equipment by preventing overuse and wear-and-tear on any single pump. This not only improves operational longevity but can also lead to cost savings on maintenance and replacements over time.

The marriage of technology and intelligent fuel management isn’t a passing trend; it’s the future – and the future looks extraordinarily efficient.