I caught up with Renee in the run up to the recent Jubilee and found her looking forward to the long weekend.

“It’s one of the great bonuses the UK does offer from time to time,” she enthused. “The bank holidays.”

Renee has been UK-based since the start of 2021 when she took on the role of managing director of UK marketing for Phillips 66 Limited with the move coming amid some of the biggest challenges of our time. “When the opportunity originally presented, there was no lockdown,” Renee explains. “Obviously Covid was already around, and I knew it would be a challenge, but I was certain that we wanted to take the opportunity and bring the family here.”

The picture changed quickly: “As I was sorting out my visa and all the details ready to move as planned, in January of 2021, the lockdown began and, with it, the requirement for quarantine. With the level of restrictions imposed in the UK, we felt the family were better served remaining in Texas where they could continue with their schools and sports.

“So, I arrived in the UK on my own and straight into a hotel to quarantine for 10 days.”

Clearly not easily fazed, Renee made the best of the situation returning to visit the family once a month despite each trip meaning another 10-days in quarantine.

“In the first half of 2021 I spent 50 days in quarantine!” Renee comments. “I was very isolated during that time, but the good part, if there is a silver lining, is that I was able to spend a lot of time getting to know my team and the business here.”

The time to focus was a real benefit to Renee but: “I was literally counting the days until my family could join me here in the UK, which they finally did in June. It was so nice when we got to that point.”

The family were on their summer break when they travelled to join Renee who was thrilled to be able to share the UK with them: “They also had to quarantine but, once we got done with that, we were able to get out and about and appreciate the things that London has to offer. It was really fun!”

Similar, but different

Now free to immerse herself, I asked Renee whether she had noticed many cultural differences. It is clear from her reply that bank holidays are not the only thing Renee enjoys about the UK.

“We all speak English, and I expected more similarities, but I have found that the American and the British cultures are very different. I really like the British culture. People are more polite and slightly reserved, and, as a result, good listeners.

Renee continues: “It may be partly where we are based – London is the epicenter of cultural diversity – and it’s great to get different perspectives. I do find the people here easy to get along with.”

Renee is a warm, engaging and instantly likeable person, and it is hard to imagine many people she would not get along with. Confirming my instincts, she adds: “Having said that, that’s really anywhere in the world as I always try to connect with people, but the people here, and especially my team have been really great.”

The Phillips 66 team have clearly played their part in making Renee’s move easier. I wondered how much time Renee spends working with them now restrictions are lifted. “I am mostly at the office,” Renee answers.

“Usually, four to five days a week. We have adopted four days in the office and one day at home right now for our London-based employees, and people really appreciate it.”

Against such a challenging backdrop, Renee speaks surprisingly positively of her move, but travel and adaptation are things she became used to from the start of her career.

“When I graduated college my first job was with a Chicago-based company called UOP that provides patents for refining technology as well as being one of the main catalyst providers.

So your very first job was in energy?

“Yes – that is how I ended up in the industry although, strangely, it was the travel that I was initially attracted to. I would have taken the job, no matter what the industry – it just happened to be energy.

“It was three years of training to become a technical service advisor. Once in that role I was permanently field-based at international locations, without a house, apartment, or anything. I rented a small storage area in Chicago, put a few things in there that I wanted to keep, and I went from job to job all over the world living out of a suitcase for about three years. It was an amazing time with the opportunity to learn about different cultures.”

“One time I was stuck in New Delhi for four days waiting for my luggage. Every day it didn’t show I hired a taxi to show me around the city.”

This enthusiasm for new cultures was clearly a significant factor in the way Renee embraced the UK opportunity despite the hurdles.

“The UK was a much easier transition for me than some other locations I’ve been. I knew this would be longer-term, but I spent time in many different places all over the world and you appreciate quickly just how good we have it in the US and Europe. Many of us take for granted the standard of living, the amenities, and conveniences. Not everyone in the world has those same opportunities so it is very, very humbling.”

The refinery of the future

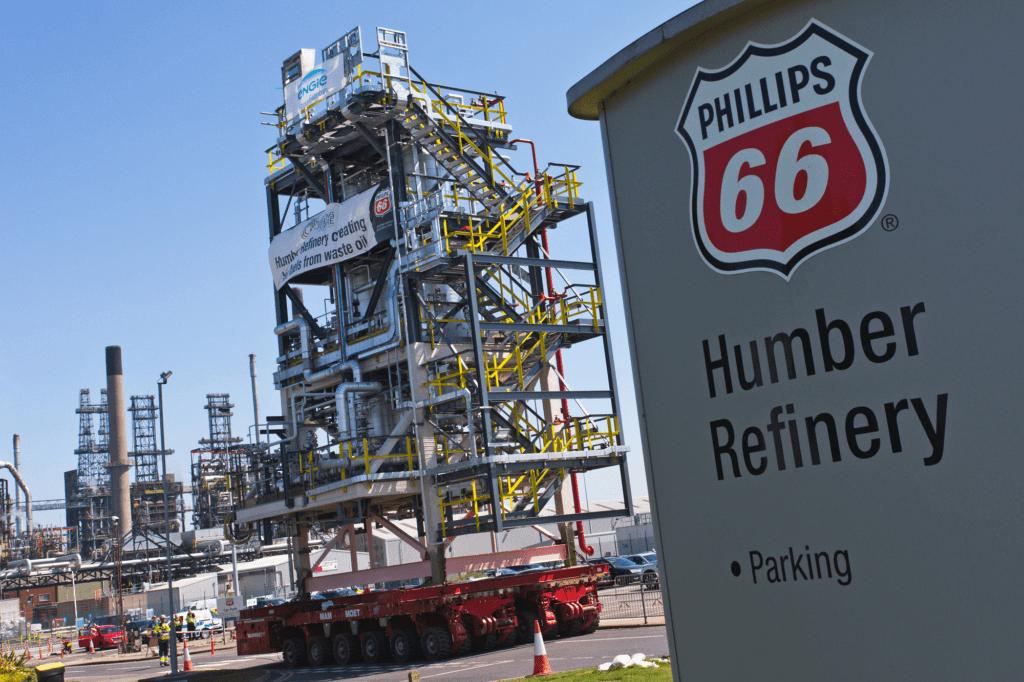

Once settled, Renee wasted no time and looks back with satisfaction at the progress made so far. The Refinery Service Station at Humber is a flagship site for Phillips 66 Limited and its rebuilding has been a huge milestone. It is the first site to trial the new JET CHARGE™ EV charger and JET™ Renewable Diesel – two extremely exciting developments driven by the main thrust of Renee’s role.

“One of my top priorities has been to establish our Emerging Energy strategy. We had started thinking about that as a team before I came over, but now we are executing the strategy, including launching new product lines, even creating a market where maybe there wasn’t one.

“Our Emerging Energy strategy is built on four pillars:

- Renewable fuels

- Battery value chain

- Hydrogen

- Carbon Capture

“We have a corporate Business Development (“BD”) lead from each of those pillars and we meet in person every six months to review strategic progress and generate new ideas. Recently we had Heath DePriest, our Vice President of our Emerging Energy Organization, over to the UK along with his BD leads from each of the pillars.

“They are excited about the UK’s role within Phillips 66 because, in all four areas, we are at the cutting edge, with the US looking to Humber Refinery, and the UK, as an example of what can be achieved. It was exciting to see their focus on our business here.”

One area where Phillips 66 is further along in the US is the conversion of an entire refinery to renewable diesel.

“It was a huge announcement,” Renee enthuses. “In the US, we also have a lot of other exciting projects in emerging energy. We have recently received a key land-use permit for the renewable fuels plant in the San Francisco Bay Area and can start breaking ground on the construction to convert the plant from a fossil fuel to a renewable fuels plant, which is a huge milestone.

“Californian legislation often supports the changes we are making and consumers in California already want that change.

“Our priority is always to meet our customer and consumer needs. If they are shifting to EV batteries, then we want to provide the components. If they want hydrogen, then we need to be able to provide that. It is absolutely about providing what they need. Listening and responding. Being agile enough to shift focus.”

Delivering Emerging Energy solutions

Making customer-focused decisions is how Phillips 66 is driving the industry evolution to future fuels as Renee explains: “We’re here to meet energy needs, whether traditional petrol and diesel or renewable fuels or power or hydrogen. What that looks like is changing and will continue to change over time, but our approach will not change – to provide energy and improve lives.”

With the scale of the challenge, where did you start?

“One of the first things we did was to look at EV charging solutions and we already have our first charger up and running at the Humber Refinery Service Station with eight more going live at two different sites very soon.

“Our research showed that consumers were unhappy with the complexity of previous EV solutions. They go to a charging point and must download an app. Then the app must talk to the charger to initiate the charge. But if the location has no wi-fi, it does not work. If customers get frustrated, they will not return.

“We wanted to make it easy and seamless and were very thoughtful about every decision. That process took a little longer, but we are confident we have made the right choices. We listened to what consumers wanted and the result is an uncomplicated design, high speed and with a tap and go payment method. No app and no membership.

“One of the concerns for our retail dealer network is declining fuel demand. We believe that EV charging will be a key part of the future forecourt offering; a successful trial of EV chargers within our company-owned retail network will enable a roll out to our retail dealer network.”

This solution will not be limited to JET- branded partners either: “The expertise we are developing will enable us to work with other businesses beyond the forecourt.”

Future fuel success

The second area Renee highlights is the development of lower carbon fuels.

“We’ve been processing waste oils, such as used cooking oil, at our Humber Refinery for some time, selling bio-propane and other lower carbon fuels. As we announced recently, that brought the opportunity to supply British Airways with sustainable aviation fuel (SAF), a replacement for jet fuel produced from a sustainable waste feedstock – another exciting milestone for our Emerging Energy initiatives and a huge company accomplishment.

“The relationship with BA is the perfect example of the Phillips 66 Humber Refinery breaking new ground and taking the lead to achieve lower-carbon air travel.”

Another achievement is the rollout of renewable diesel both as a wholesale and retail product.

“We offer renewable diesel as a wholesale product from Immingham, and have recently extended that to a retail product for HGV’s – JET™ Renewable Diesel. I went to the site just after the product was launched, with all the new branding, and was excited to hear that we had our first couple of fill-ups at the HGV forecourt.

“I believe renewable diesel could have a key role in the transition,” Renee continues. “It enables us to use existing infrastructure and equipment, with significant reductions in fuel lifecycle Greenhouse Gas (GHG) emissions without significant investment.”

And with many in the UK referring to the product as HVO, Renee explains why Phillips 66 Limited is using the term ‘renewable diesel’: “We don’t feel that HVO is an accurate description of the product because it is not necessarily hydrotreated vegetable oil. This term emerged when only vegetable oils (e.g. rapeseed, soybean and corn oil) were used as feedstocks, however, with the advancement in production methods allowing the use of waste fats, oils and residues, feedstocks are now not limited to vegetable oils and renewable diesel sold by Phillips 66 Limited and JET™ Renewable Diesel is derived from biomass sources such as used cooking oil, fats, greases and vegetable oils.” [The term renewable diesel is also used for similar product in the US]

The belief Renee has in future demand for lower-carbon liquid fuels will be well-received by the industry. Once overlooked as a future energy solution, it seems that the industry investment in changing that narrative has finally earned renewable diesel a place at the table.

Renee agrees: “Momentum is building within our company along with a lot of excitement about the transition. A couple of years ago there was a bit of a cloud over our industry with people concerned about the future and concerned about a declining market.

“Fast-forward and now we are all really enthused about the opportunities it offers. It is an exciting time to be in the industry that will provide the solutions. We have great engineers – smart people with an understanding of how to execute projects and are willing to invest substantial amounts of capital.

“We are starting to see these projects ramp up, especially at our Humber Refinery where there are some big projects underway including Humber Zero, a carbon capture and storage project and the Gigastack green hydrogen project – as we look to lower the refinery’s greenhouse emissions and progress toward the refinery of the future.”

The Humber Refinery is also the only producer of specialty graphite coke in Europe, an essential component used in the EV supply chain, helping to substantially lower the transport sector’s greenhouse gas emissions. Alongside successfully driving the Emerging Energy strategy, Renee’s time in the UK has also been one of managing crises in traditional fuel supply, ensuring distribution channels were kept open to serve Phillips 66 Limited’s highly valued customers.

“We had great feedback from our wholesale and retail customers,” Renee comments, reflecting on the challenges they have had to deal with. “I think that is, in part, because we have strong, open channels of communication. We listen and, in doing so, we have a steer on what our customers want and need.”

Shifting perceptions

Given the clear commitment at Phillips 66 to deliver lower-carbon energy solutions and given that the industry is best-placed to develop and implement those solutions, it seems strange that there is such a disconnect between the understanding of the industry from within and the way it is viewed by consumers.

I asked Renee her view of this and what could change it.

“I even have this discussion with my own children,” Renee comments. “They’ve been exposed to my work their whole lives, and they still debate with me. I explain to them how we rely on our base business to fund investments for a lower carbon future.

“That they have a tough time understanding, even having a mom that works in the energy industry, highlights the scale of the problem – especially with the younger generation. But we have done a good job here in the UK talking about what we are doing and need to continue to get our message out there. When people start to see hydrogen trucks on the road, for example, and one day they may say ‘powered by Phillips 66 Limited’, then attitudes may start to change.

“Government advocacy is also important at this time to ensure decisions are made that help us to facilitate the transition.

“That’s why we recently added new positions in London in support of Emerging Energy. Simon Holt is now our manager of Emerging Energy for Europe. Simon has been with the company for many years and was already working on Emerging Energy in his prior role. We also brought on Callan Tree as Government Affairs Specialist, and we are lucky to have him on our team.”

Does Renee believe that producers could be doing more to actively drive the future energy narrative?

“Oh absolutely, we must drive the narrative. “The 10-point plan was an important milestone for the UK to give clear understanding of the direction. Many of our projects are multi-year initiatives so it’s important to have clear policy and direction. “It is also essential that we understand the funding because, in some cases, subsidies are required for these projects to be economically viable.

“It is also important to come to the table and explain where things are not working or where we see a gap in the plan. We can help the UK government to understand how we can fill that gap and where we might need support to do that.

“The plan is a bookend with one side where we are today, and the other where we are headed. The gap between is the bridge and nobody knows exactly what that will look like. We don’t necessarily have all the pathways in place to get from point A to point B so it will still be a long and winding road as we evolve over the next couple of decades.

“The plan did give clear direction on green hydrogen and carbon capture and storage, both of which are critical to our strategy, but I think lower carbon, liquid fuels will be a key part of the transition. I believe there will be room for renewable diesel for a number of years. For commercial users it is an economical way to reduce their carbon footprint with immediate effect until, for example, their fleet is ready to be replaced.

“I believe the long-term solution will be multi-pronged. Looking 20 years ahead, it is impossible to believe that all energy demand will switch from fossil fuel to one or two solutions, as certain sectors are extremely difficult to de-liquefy – such as aviation. For mobility, the transition from liquid fuel combustion engines to EV is already happening. The future is likely to see a combination of hybrids, EV battery vehicles, and, potentially, hydrogen for HGVs.

“With increased electrification, the demand for liquid fuels reduces. As technology advances and demand drops, the availability of lower carbon liquid fuels will increase for those areas where it is the best fit.”

The right fuels in the right places

Asked if fossil fuels will be here for the long- term Renee doesn’t hesitate: “Absolutely! If you consider that our Humber Refinery makes a key component of the EV battery supply chain – battery graphite coke. The demand for that is increasing significantly. It is produced in conjunction with conventional fuels, so these fuels will continue to be produced to facilitate the production of the EV battery supply chain.

“It is interesting to consider that our liquid fuels will eventually become the by-product and inland placement of those fuels will continue to be part of our integrated strategy. We will manufacture energy (in all its guises) to meet the energy needs of the UK, and we will continue to do this while we are transitioning. Transitioning takes time and it is vital that we continue to provide petrol and diesel for those who rely on it in their day to day personal and work lives.

“The core business at Phillips 66 Limited is supporting the investment for the future fuels work.”

This highlights why carbon capture is one of the four Emerging Energy pillars for Phillips 66 as Renee confirms: “Future lower carbon plans cannot be achieved without green hydrogen and carbon capture. They will have the biggest impact and are absolutely required to reach the lower carbon goals. Given the support of the corporation and direction from the UK government in terms of the 10-point plan, our intention is to process lower carbon feedstocks, produce lower carbon liquid fuels, including renewable products and EV battery coke.

“We call it ‘Fuelling the Future’ and Humber is well on its way. We started processing used cooking oil in 2018 so we are ahead of the game.

It is not an easy process – from sourcing feedstocks, establishing support logistics and understanding impacts on our processes (and the refinery’s units) to ensure we maintain the highest standards of safety. We started at a low volume, constantly evaluating to determine how we increase to the next level as we continue to grow the volume of waste feedstocks. We’re also now processing, on an interim basis, tyre pyrolysis oil which is an exciting area to be in. It is derived from tyres that would otherwise end up in landfill. The tyres are broken down into various components, including liquid product, that can be run through the refinery with the potential to create lower carbon products. It’s a lot more challenging than processing used cooking oil, but another important project that highlights why existing energy companies are so vital to future solutions.

“New companies in the UK looking to produce lower carbon fuels have to basically build a mini refinery to remove impurities and produce the final product. Our industry may be viewed as being at a disadvantage in this environmentally conscious world, but we see it as a great benefit – we’ve got the kit that can be adapted to do something different.”

What are your thoughts about the next generation who will be helping shape the future of our industry?

“I think we are becoming more appealing to younger people as they start to understand what we are doing and that, especially here in the UK, we are on the leading edge.”

Renee explained how Phillips 66 Limited takes every opportunity to get these messages into the community.

“In February, seventeen engineering students from Engineering UTC Northern Lincolnshire were hosted at the Humber refinery to celebrate International Women and Girls in Science Day and spent time learning about opportunities in STEM from our chemist interns and engineers.”

How have you found it yourself as a female in this environment?

“I don’t feel l like I am treated differently as a female, but I do feel we still have room for improvement and to create more opportunities for women. If you look at our board of directors, we are doing a really good job. Five out of 13 members of our Phillips 66 Company Board of Directors are female. We have come a long way and our leadership team looks to create opportunities not just for women but also for people of colour, of diverse backgrounds as well as from the military. It has been refreshing to elevate the dialogue around diversity and inclusion.

“There are still times when I am the only woman in the room, and that happens quite often, but it is an environment I’m very comfortable with and that I’ve worked in my entire career. Every now and then I notice it and it still surprises me that there aren’t more women in some of these situations.”

Renee’s passion for the energy industry is abundantly clear though she did have a brief break from it.

“I worked in a different industry for about a year and a half while my husband was in Graduate School, and I just couldn’t wait to get back to energy. In our industry we have extremely high standards, strong safety standards and good documentation, processes, and procedures.

“All things I took for granted until I was away from it.”

Given her obvious commitment, I wonder if Renee has time for anything other than work and family?

“It’s important to me to prioritise and make time. I recently went to see a play running here in London called Life of Pi and it was so good, fantastic! I would recommend that to anyone, even if you’re not really into plays. I’ve got two concerts booked as I finally decided I need to take advantage of the music scene here, so I’m going to see Green Day and Duran Duran.”

Renee is someone who knows where she is heading and has a plan to get there, but also someone happy to learn from those around her. I ask what is the best advice she has ever been given?

“To work hard and stay humble,” she answers. “And to never forget where I came from, which was, very much, humble beginnings. To appreciate all the things that you have been blessed to have and to pay it forward as well as to give back.”

It strikes me that Renee’s personal attitude of appreciating what she has been given and paying that back is echoed in her approach to her role at Phillips 66. What would she regard as success in this role?

Renee ponders before answering: “For me to consider this a successful time would be to grow the business in an evolving market. That is obviously not easy to do. The only way to do it is to expand our portfolio and that is what we are doing.”

In a final thought, Renee shares the one thing she would want to say to customers of Phillips 66 Limited:

“We’re here for the long haul. It’s a marathon, not a sprint.”