The Prax Group has signed an agreement with Total to purchase Lindsey Oil Refinery and its associated logistic assets. With a strong track record of integrating acquisitions and managing assets in the oil value chain, the Prax Group is a long-standing and trusted partner of Total.

The acquisition will bring new investment to the refinery and underlines the Prax Group’s determination to support the local economy and the wider community.

“The Prax Group’s long-term strategy is to be fully integrated across the oil value chain from upstream to downstream,” said Sanjeev Kumar, CEO of the Prax Group. “Acquiring Lindsey Oil Refinery is a natural progression for the Prax Group, providing the opportunity to integrate the refinery and associated product flows into the company’s UK distribution and retail footprint, which operates under the Harvest Energy brand. We look forward to continuing to provide a secure supply of energy to new and existing customers.”

The sale will place the refinery at the heart of the Prax Group’s strategic network. Sanjeev Kumar continued, “We are committed to all Lindsey Oil Refinery employees, who are a key element for the future success of the refinery.”

Lindsey Oil Refinery saw a major investment from Total in 2015, which modernised and streamlined the refinery.

“Since selling our British retail network in 2011, the Lindsey Oil Refinery has not been part of Total’s downstream system. With this agreement to sell, the refinery will be at the heart of the Prax Group’s UK network and it will be able to add value more easily”, said Thomas Behrends, general manager of Lindsey Oil Refinery. “We are proud of the team and the work we have accomplished together.”

The completion date of the acquisition is expected before the end of 2020.

After 60 years of trading, the parent company for Isle of Wight Fuels (IOWF) has decided to close the business, which includes the Isle of Wight’s only fuel storage depot, in less than 2 weeks’ time, resulting in concerns over knock on effects for customers and companies in the supply chain.

The company provides homes and businesses with vital heating oils, as well as supplying diesel and petrol to local filling stations, commercial operators and agricultural industries. With the closure of the depot in early August, the island will be reliant on fuel being brought over by tanker on cross-Solent ferries. Any disruption to this cross-Solent travel, fare increases, or regulatory changes could have serious knock-on effects to those on the island.

Over 1.5million litres of fuel passes through the Kingston Road facility in East Cowes each week and the depot can store a total of 3million litres, providing a good level of resilience. Once the depot closes – with the loss of around 15 jobs – the Island will be solely reliant on fuel being brought over by tanker on cross-Solent ferries, with no option to store a reserve.

The decision came after Motor Fuel Group, IOWF’s parent company, carried out staff consultations and a detailed examination of the trading options.

A statement from Motor Fuel Group reads;

“Following a detailed examination of the trading options of IOWF together with individual consultation with all members of staff, Motor Fuel Group announces that it is not viable for the business to continue to trade.

“Accordingly, and with regret, the IOWF business will close on Friday 7th August 2020.

“No fuel deliveries will be made, nor customer orders accepted, after this date.

“We would like to thank our customers for their loyal patronage and our staff for their professional and dedicated service.”

Ensuring continuity of supply

For the past 18 months, supermarkets on the Island have been sourcing their own supplies which are delivered by road tanker. However, the smaller and more rural filling stations are still supplied by Isle of Wight Fuels and Certas Energy – and Certas get their supply from the fuel depot in East Cowes too. If supplies were to run low at independent stations motorists may be forced to fill up at supermarkets, which could, in turn, see supplies depleted there quicker than normal.

A spokesperson for Certas Energy has said;

“We currently supply around a third of the fuel on the Isle of Wight across the various sectors. We are working closely with all of the relevant authorities and stakeholders to ensure continuity of supply for the whole island.”

Aside from the loss of jobs, the small businesses who provide services to IOWF will also feel a knock-on effect.

Karl Love, the Isle of Wight councillor for East Cowes shared his concerns, both in a commercial and domestic sense, over the closure;

“It is important to understand the supply chain and impact. It’s not a simple case of bringing other suppliers to our Island, because they will have to learn the delivery routes and routines of Island people in making that delivery.

“I would hope that someone might purchase the company and consider introducing the supply of fuels by ships rather than carrying it in small tankers across the Solent on passenger ferries.

“We should not forget the loss of these jobs and its impacts on families. It is a skilled job requiring lots of safety training in order to handle inflammable fuels.”

Just 18 months after breaking ground, Europe’s most advanced, 100,000 tonnes per annum, used lubricating oil re-refinery, AVISTA Green’s in Kalundborg, Denmark, is operational.

The construction of the re-refinery has been realised through an international joint venture between Germany’s AVISTA OIL and Slicker Recycling from Stourport in the UK. They are both among the leading used oil collectors in Europe and responsible for supplying the volumes needed to feed the plant. The used oil is primarily collected from vehicle repair workshops, industrial companies and waste recovery sites throughout Europe and delivered to the plant either by truck or ship, mooring at the company’s dedicated jetty.

“We are proud of having succeeded with such a big project in such a short timeframe,” said Leon Sloth Skovbo, managing director, AVISTA Green. “Today, we have Europe’s state-of-the art re-refinery that transforms used lubricating oil into high quality base oil, turning a waste product into a reusable material, contributing substantially to sustainability and the circular economy.”

Despite the worldwide pandemic cancelling the original planned opening ceremony, the AVISTA Green team remain in high spirits and are eager to start production. Following months of hard work, from permitting and planning through to construction and commissioning, the re-refinery is now ready to transform its first litres of used oil.

Environmental profile

As indicated by the name, AVISTA Green has an environmental profile. Passing through the plant, the used oil is up-cycled back into high-quality base oil ready for re-use in the production of new finished lubricants. These lubricants will return to the re-refinery as used oil in a continuous cycle to be re-processed again, both in keeping with the European waste hierarchy and circular economy philosophy. The innovative technology used in the new facility is more environmentally friendly and efficient than conventional processes. Such re-refined base oil emits as much as 30% less CO2 than new base oil produced from crude.

Peter Jonsson, technical director said; “We have managed to keep all the specialist expertise and experience within our company by retaining the core of our skilled process operators during the construction of the re-refinery. During the last months they have been busy training new colleagues.”

The new re-refinery has been designed to meet the highest technical, environmental and safety standards. The plant is fully energy optimised including the recirculation of all surplus heat. Modern laboratory facilities are available for total quality assurance, from receipt of feedstock right through to the delivery of the final re-refined base oil. Safety remains a priority where the plant design, equipment, systems, controls and processes have all been implemented to keep employees, the environment and process integrity safe.

Leon Sloth Skovbo added; “We are looking forward to a bright future. The global focus on environment and climate will continue to grow strongly in the future, and here we see ourselves as a significant and important player.”

Logistics UK (the new name for FTA), has reacted positively to the changes to the Driver Certificate of Professional Competence (CPC) by government, which became effective 22 July 2020. As James Firth, Logistic UK’s head of road freight regulation says;

“It is now important that any changes made to the laws governing what is already a highly regulated industry should acknowledge that no two drivers are the same and provide capacity for tailoring training to meet individuals’ needs.

“During the negotiating process, the representative body ensured that any changes did not make the DCPC overly prescriptive,” he said, “and we are pleased that the ability to identify what training a professional commercial vehicle driver needs remains with industry – be that employer or driver themselves – rather than with politicians.”

Biggest change since inception

The changes to the certification, which cover amendments to minimum qualifications, training standards and the delivery of periodic training, as well as exemptions for drivers in specific industries, are now in force in the UK. The new directive has not imposed training rigidly – as it was feared it might – but now emphasises the importance of adapting and tailoring training to the individual’s own role, including relevant legal and technological developments, and remedial training as appropriate – mirroring the way the Directive has historically been implemented in the UK.

The most noticeable change will be the inclusion of a new flexibility around e-learning. Courses will be able to be designed to allow delegates to take up to two hours of a seven-hour course as e-learning content the day before a classroom session.

“This is the biggest change in delivery of Driver CPC since its inception in 2008,” continues Firth. “We will see how the training industry takes the option up, but we are pleased to see DVSA is looking for new ways of allowing delivery within the constraints of the Directive.”

Logistics UK has stressed that the term “e-learning” should not be confused with “distance learning” or “remote learning” which has been deployed as part of the emergency response to the Coronavirus outbreak. DVSA has indicated that it will next examine the continued use of distance learning in Driver CPC in September.

Name change reflects representation

More detailed information on the changes can be found in a member briefing note produced by Logistics UK, whose name change from FTA was originally planned for earlier in the year but postponed due to the COVID-19 crisis to focus on supporting members. David Wells, chief executive at Logistics UK, commented at the time;

“FTA is strong because of its size and scale and because we already represent all of logistics, a very large sector critical to the success of UK plc. The name change to Logistics UK is a natural progression and makes it more obvious to stakeholders, like policymakers and young people looking to develop a career in logistics, that we are the only business group that represents the whole industry. I believe this change will strengthen our position and give us a great opportunity to achieve even more for members in the months and years to come.”

With COVID-19, Brexit, new technology and other disruptive forces driving change in the way goods move across borders and through the supply chain, logistics has never been more important to UK plc. Logistics UK supports, shapes and stands up for safe and efficient logistics, and is the only business group which represents the whole industry, with members from the road, rail, sea and air industries, as well as the buyers of freight services such as retailers and manufacturers whose businesses depend on the efficient movement of goods. For more information about the organisation and its work, including its ground-breaking research into the impacts of COVID-19 on the whole supply chain, please visit www.logistics.org.uk.

More

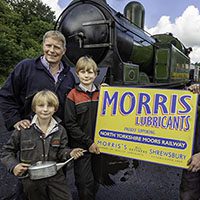

Morris lubricants has agreed to support 50 heritage and steam railways across the UK which have been closed due to the coronavirus pandemic.

Shrewsbury-based Morris Lubricants has worked closely with steam heritage workshops during its 150-year history and has great experience in formulating lubricants specifically for the sector.

The Morris Lubricants Heritage Railway Support Scheme, launched in April, aims to reward customer loyalty and support heritage and steam railways through these difficult times.

Andrew Goddard, executive chairman of Morris Lubricants, said that, as dedicated enthusiasts and supporters of the heritage and steam industry, the company was keen to support railways.

“We understand that it’s a difficult time for heritage railways in this pandemic and wanted to support them in any way we could,” he explained.

“Morris Lubricants has a long tradition of supplying these railways with our top-quality steam lubricants. We particularly wanted to reward the loyalty of our existing heritage railway customers and I am pleased to report that the support scheme has attracted others to use our products.”

Railways were invited to apply to the scheme explaining why they needed support and how Morris Lubricants could help. The response was excellent, and the company has agreed support packages that include discounted or free lubricants and promotional material.

Steaming into the future

One of those to receive support is The North Yorkshire Moors Railway (NYMR), an award-winning charitable trust that carries 300,000 passengers annually from Pickering to Whitby.

Matthew McCrudden, an HGV technician based in Abbey’s Middlewich depot, completed the tough Three Peaks Challenge in under 24 hours.

Matthew took on the challenge, as part of a team of eight, to raise money for A Stroke of Luck, a charity offering advice and access to exercise-based stroke recovery.

The challenge involves climbing the three highest peaks in Britain, totalling 26 miles of walking and 3,407 metres of climbing, in 24 hours. The team tackled Ben Nevis first, the tallest of the peaks, followed by Scafell Pike and finally reaching Snowdon in North Wales.

After successfully completing the Three Peaks Challenge, Matthew said; “The climb was incredibly tough at times, but we were motivated by knowing the donations were rolling in and we were all making a difference to each of the charities we were supporting.

“I’m very grateful to the fantastic team who climbed with me and to everyone who has donated to help support the amazing work A Stroke of Luck are doing to help stroke survivors on their road to recovery.”

To show your support and donate to help with the important work A Stroke of Luck are doing, please visit Matthew’s just giving page here:

https://lnkd.in/gbCyQS8

The Logistics Emissions Reduction Scheme (LERS), run by Logistics UK (formerly FTA), has announced that entries are now open for its Leadership in Emissions Reduction Award, sponsored by ExxonMobil. The award recognises and celebrates the logistics company most committed to reducing emissions and leading the way in environmental excellence.

The winner will be presented with the accolade at Logistic UK’s Logistics Awards 2020 which. this year, will take place on 10 December at the Park Plaza Westminster Bridge, London.

Natalie Chapman, head of urban policy at Logistics UK, comments; “With an urgent need to improve air quality across the UK and to achieve net zero greenhouse gas emissions by 2050, logistics businesses are striving to reduce emissions from their operations. This award is the perfect opportunity to recognise and celebrate the company which, through the use of alternative fuels and improved fuel efficiency, is making a significant contribution towards a greener future and paving the way for others to follow.”

The award is open to all members of LERS, a free-to join initiative to record, report and reduce carbon emissions from freight transport, administered by Logistics UK (the new name for FTA). The closing date for entries is 21 August 2020. To enter, or for more information, please visit: lers.org.uk/home/lers-awards

For more information on LERS, including how to join, please visit: http://lers.org.uk/

Pictured left to right: Gaz Owens, Ryan Evans, Greg Walters and Steve Cristofaro. Picture by Marketing Manager, Jake Hicks, at the opening of the GTBAL Our Place store, in April 2019

Valero Operations Shift workers at the Pembroke refinery have donated another £25,000 to charity.

The previous generosity of this Valero team was reported in Fuel Oils News’ June issue, when a donation of the same amount was given to PATCH (Pembrokeshire Action to Combat Hardship) to help those in need during the pandemic lockdown.

As well as PATCH, this time donations have gone to three local charities focusing predominantly on mental health; Get the Boys a Lift (GTBAL), PATCH and SNAP Pembrokeshire.

A Valero spokesperson said; “A huge well done to our operations staff for raising funds to help support those that need it the most.”Messages of thanks

Since the opening of its shop in April 2019, GTBAL has provided free counselling and follow-up sessions to over 110 people.

GTBAL’s Ryan Evans said; “The mental health impact that COVID-19 has had and will continue to have is immense. Everyone needs to recognise that this pandemic will impact our communities in so many different ways. Helping those who have found this a tough time is the right thing to do. Thank you, Valero staff.”

SNAP is a specialist playgroup that helps children with additional needs with their development and education.

SNAP’s Cindy Jenkins commented; “This donation will help many families who are struggling with childcare for vulnerable children in this really difficult time. It is amazing that Valero staff are reaching out to help those in need. It won’t be forgotten.”

Valero has worked with PATCH over the years. Since 2008, the charity has been giving free food parcels, clothing and household items to those in financial need in Pembrokeshire.

“Valero has already given us the largest donation we have ever received but to have even more is beyond our expectations,” said Tracy Olin. PATCH manager. “Valero staff have really done something special and we can’t thank them enough.”

Stephen Thornton, manager public affairs, concluded; “The shift workers from the Valero Operations Department at Pembroke refinery have again performed an act of overwhelming generosity. They have chosen three well-loved causes in our county focusing pre-dominantly on mental health. This pandemic has reached into all our lives and the best we can do is to continue to help and look after each other.”

UKIFDA has submitted its views on the government’s ‘Future Support for Low Carbon Heat’ and ‘Energy Efficiency in Existing Homes’ consultations.

Thom Payne, head of offshore, rigs & wells at Westwood Energy discusses the cautious rallying of the oil market, and the direction of travel, for what has been a turbulent 2020 for the industry.

For the oil markets, the first half of the year saw extraordinary swings in supply and demand, culminating in what is now thought to have been a staggering 22mbbpd of oversupply in April as OECD economies headed into lockdown and OPEC+ cuts dissolved. Demand fell to 78mmbpd and Saudi Arabia pumped an additional 1.6mmbpd, driving Brent down to under $10/bbl on April 21st and briefly pushing the WTI futures contract into negative territory.

Since then the supply demand balance has improved remarkably. A big, new OPEC+ agreement saw a 9.7mmbpd cut come into effect in May and now extended through July. To date, monthly compliance has averaged 96%, with Saudi Arabia compensating as usual for OPEC laggards and Russia adhering to its 2.5mmbpd pledged cut . More recently, a July meeting of the JMMC agreed to taper cuts to 7.7mmbpd from August through to the end of the year (a further reduction to 5.8mmbpd is then planned through 1Q2022). The effective cut could be nearer to 8-8.5mmbpd for August/September if the suggestion that serial non-compliers such as Nigeria and Iraq make up for any shortfalls in compliance in May and June. Out with OPEC+, supply has fallen by around 3mmbpd since March and in the US the EIA reports a 2.1mmbpd fall in crude production in June from a 13 million barrel a day peak in the first quarter of the year.

Westwood now estimates that overall oversupply for the first half of the year was 7.6mmbpd. However, the subsequent rapid reduction in output, coupled with US-led demand recovery, has now likely seen the global oil market flip to a net draw position of 1.3mmbpd in June. This switch to an undersupplied market will be critical to eroding the estimated 1.2 billion barrels of excess supply accrued in storage between January and May. This process looks to have already begun. According to the IEA, oil in floating storage fell by 16% in June and the EIA reported a draw in commercial crude stocks in July for the first time since March. Another indication of the rapidly shifting supply/demand dynamic is the almost $7/bbl swing in the Urals/Brent differential between April and May, as recovering Chinese refiners paid a premium to secure diminishing, yet still heavily discounted Russian crude.

The outlook, of course, remains a minefield of uncertainty. On the supply side the two burning questions will be the ability of Saudi Arabia to continue to marshal cut-compliance if oil prices continue to rise, as well as the ability of US output to recover at $40-45/bbl WTI. Whilst the CEO of Parsley Energy, Matt Gallagher, recently declared that US production will not reach 13mmbpd again in his lifetime (he’s only 37!) others such as Noble, Continental & ConocoPhillips have already announced their intention to bring back some of the capacity curtailed over March-June.

On the demand side, the outlook is even more up in the air . The most recent IEA demand outlook suggests that whilst the height of demand destruction back in April may not have been as bad as first thought, third quarter recovery will now likely be slower than previous estimates, as China reduces its strategic crude purchases and regional lockdowns threaten OECD economies once more. Even by the fourth quarter, consumption is likely to retain at least a 3-4mmbpd kerosene-shaped hole year-on-year due to international quarantines and a reduced appetite for air travel.

Westwood estimates that 3Q could see an average draw of 5.2mmbpd over the balance of the year, dropping to 1.6mmbpd for 1H2021. This assumes OPEC+ compliance remains above 95%, and US oil production grows only marginally and that the IEA’s latest demand projection plays out. Under this scenario the supply glut would be eroded to pre-pandemic levels by August of next year. This should support oil prices moving to the $50-$55/bbl range in 2021. Beyond this, the uncertainties multiply, not least the potential 4.2mmbpd of exports that are currently off the market from Iran, Libya and Venezuela, which loom large and may yet derail any price recovery in the next couple of years.

Most Read