search | waste

...emission-free travel in the not so distant future. Companies like Velocys, for example, are already leading the way in innovation that enables sustainable fuels made from waste materials to be...

...of the high hazard transportation and distribution sector, such as companies working in fuels and oil, chemicals, lubricants, LPG, liquid and hazardous waste as well as non-hazardous tanker operators. Risk...

...offer supporting features to ensure suppliers are optimising their logistics and not incurring wasted time or money.” You asked – BoilerJuice delivered “The other new feature is our upcoming Order...

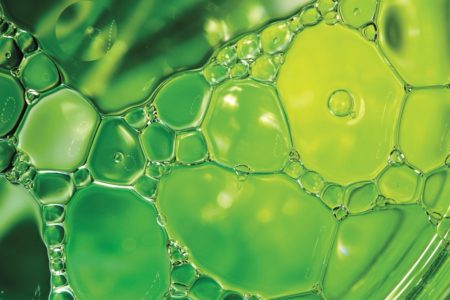

...two organisations have successfully demonstrated the use of the renewable liquid fuel, HVO, in 150 properties across the UK. HVO is derived from waste cooking oil and is a direct...

...things to waste my money on than crackers! 2. Have Yourself a Merry Little Christmas–Judy Garland version from Meet Me in St Louis. 3. Roast potatoes, veggies and Yorkshire pudding....

...sector has continued to invest heavily in projects to help the UK achieve net zero with Fulcrum BioEnergy and Essar announcing plans for a waste-to-fuel plant in the North West...

...and waste, in equal measure. If you were on ‘Mastermind’ what would your specialist subject be? One of capitals of the world, European history or petrol filling stations of Great...

...having experience in the industry from his time with NWF Fuels and Certas Energy. QM Recycled Energy QM Recycled Energy (QMRE), the Kent based specialist operator of plastic waste-2-oil systems,...

...UK to process used cooking oil. The refinery converts UK & International waste streams to finished bio road fuels. In a significant investment that expands the refinery’s capability to process...

...as expanding their products to include cleaner, lower-carbon, renewable fuels, and biodiesel from waste presents another promising avenue being explored. These actions not only reduce the fuel industry’s environmental impact...

...latest FIA regulations and has been specifically developed to demonstrate the environmental benefits of the latest sustainable fuel technology. The main components are second generation biofuel (manufactured from agricultural waste)...

...is access to a reliable, continuous supply of feedstocks of the requisite credentials and provenance, be they waste, used cooking oil, animal fats, vegetable oils, etc. to be able to...

...on the brink of evolution despite scalability challenges. “The innovative production of SAF, using resources ranging from agricultural waste to the pioneering ‘efuels’ generated from carbon capture and green hydrogen,...

...renewable energy supply chain.” Existing support for food-based biofuels will end in 2020, with greater support being given to second and third generation fuels produced from agricultural or urban waste....

...government, including a potential ban on diesel engines by 2035. CNG Fuels already supports major fleets with 100% renewable biomethane sourced from food waste and manure across its UK-wide network...

...mean, that’s practically a waste of a subscription, right? But if I don’t stick to my routine, I get cranky, so I do my best! Images supplied by Claire Foster,...

...a second-generation biofuel from Coryton that contains zero fossil fuel and is manufactured from agricultural waste and by-products from crops which can’t be used for consumption. With no modifications to...

...Greenergy, a leading supplier of road fuels and Europe’s largest manufacturer of biofuel from waste, will allow more students to see what careers are available on their doorsteps and to...